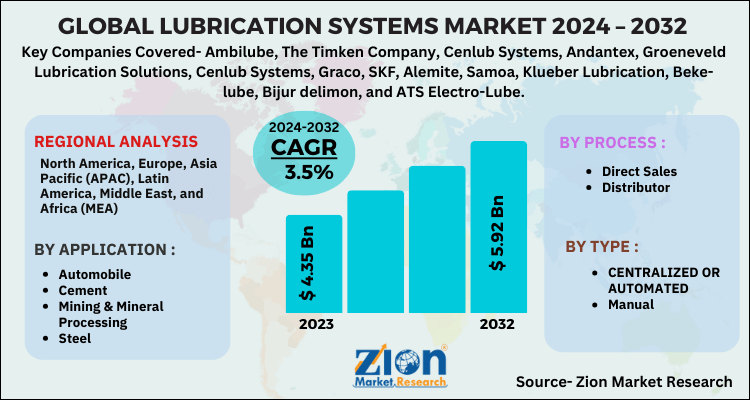

In the world of industrial machinery and automotive engineering, few principles are as universally acknowledged as the critical importance of lubrication. Without it, metal grinds against metal, friction generates destructive heat, and even the most robust components face rapid, catastrophic failure. Lubrication systems Market are the engineered circulatory networks that deliver this essential lifeblood—oil or grease—to the right place, at the right time, in the right quantity. This article explores their function, types, key components, and the vital role they play in modern industry.

The Core Function: More Than Just Reducing Friction

While reducing friction and wear is the primary goal, a well-designed lubrication system performs several simultaneous functions:

-

Heat Dissipation: It carries heat away from critical components like engine cylinders or bearing assemblies.

-

Contamination Control: It suspends and transports wear particles, sludge, and contaminants to filters for removal.

-

Corrosion Protection: It forms a protective film on metal surfaces, shielding them from moisture and corrosive agents.

-

Power Transmission: In some systems (e.g., hydraulic systems), the lubricant itself acts as the power-transmitting medium.

Types of Lubrication Systems

Choosing the right system depends on the machine’s speed, load, complexity, and operational demands.

1. Manual Lubrication

The simplest method, involving handheld grease guns or oil cans. It is labor-intensive, inconsistent, and suitable only for low-speed, non-critical, or standalone equipment. The risk of human error (over- or under-lubrication) is high.

2. Automatic Lubrication Systems (ALS)

Also known as Centralized Lubrication Systems, these are the standard for modern industrial machinery. They deliver precise, measured amounts of lubricant from a central reservoir to multiple points automatically. Key subtypes include:

-

Single-Line Parallel Systems: Use a single main supply line with individual injectors/dividers serving each lubrication point. Easy to monitor and modify.

-

Dual-Line Parallel Systems: Utilize two main lines alternately pressurized, ideal for heavy-duty applications and large machinery with many points.

-

Progressive Systems: Lubricant flows through a series of nested pistons in a progressive divider valve, moving in a sequence. A blockage at one point stops the entire valve, providing inherent blockage monitoring.

-

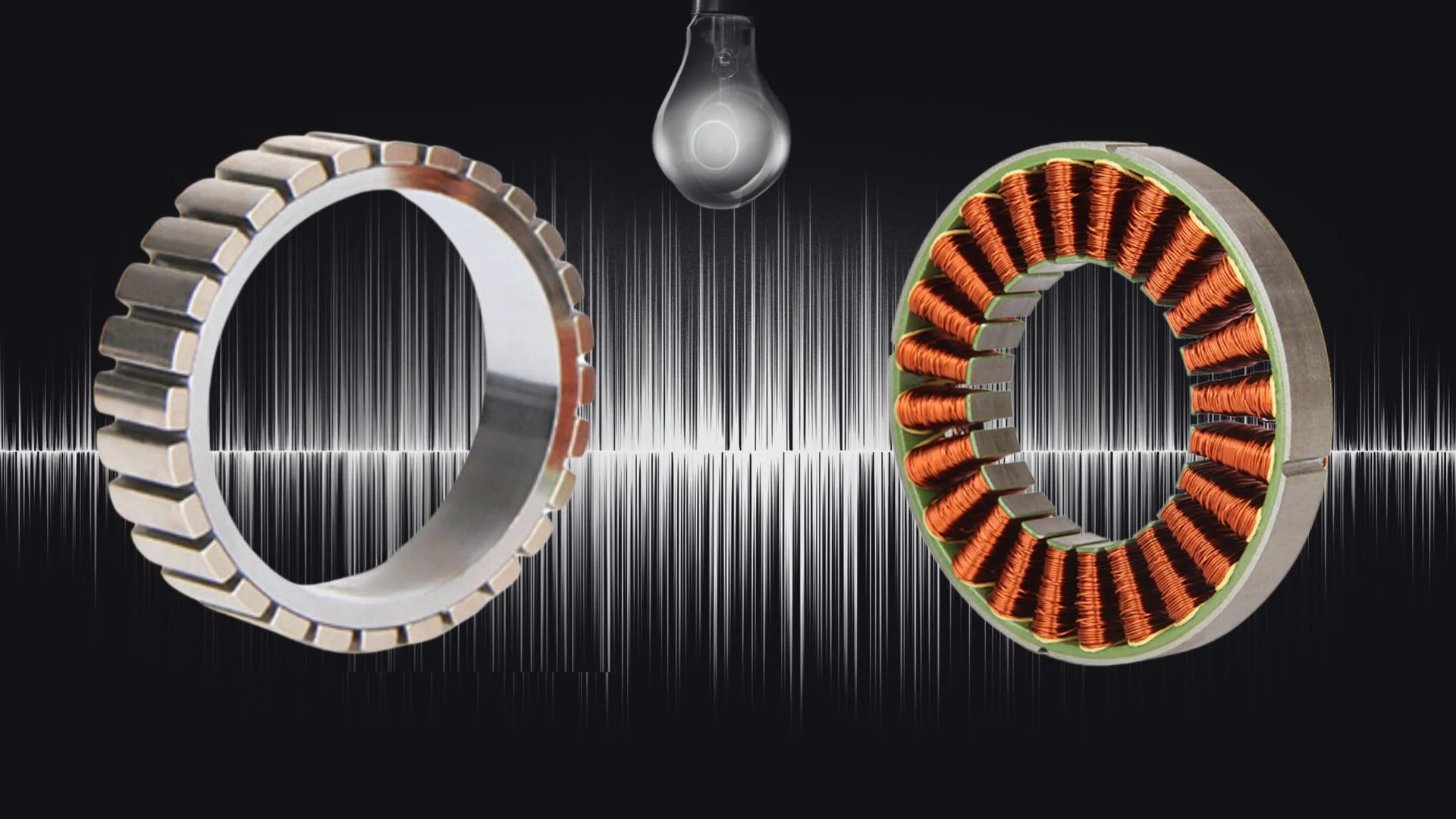

Oil-Mist Systems: Atomize oil into a fine mist carried by air to bearings. Excellent for cooling in high-speed applications like spindle motors and some turbines.

3. Circulating Oil Systems

Common in large turbines, gearboxes, and engines. Oil is pumped under pressure from a central reservoir, passes through filters and coolers, lubricates components, and drains back to the tank for re-circulation. This is a closed-loop system offering superior cooling and contamination control.

4. Splash Lubrication

Used in simpler enclosures like gearboxes and early engine crankcases. Rotating components (e.g., a gear dip) splash oil onto surfaces or into collection troughs that channel it to bearings. Simple but limited to relatively low-speed applications.

Key Components of a Modern System

A sophisticated ALS or circulating system comprises several integrated parts:

-

Reservoir/Tank: Stores the lubricant, often with level indicators (sight glasses or sensors).

-

Pump: The heart of the system. Can be electric, pneumatic, or mechanical, providing the motive force.

-

Controllers/Timers: The brain. Electronic controllers activate the pump at set intervals and durations for precise control.

-

Dividers/Metering Valves: Distribute and meter the exact lubricant volume to each application point.

-

Supply Lines & Fittings: The “arteries and capillaries,” delivering lubricant from the pump to the points.

-

Filters: Remove particulates to protect both the lubrication system and the machine components.

-

Sensors & Monitors: Provide critical feedback on pressure, flow, tank level, and system health, enabling predictive maintenance.

The Rise of “Smart” Lubrication: Industry 4.0 Integration

The next frontier is the integration of lubrication systems with Industrial IoT (IIoT). Modern systems can feature:

-

Cloud-Connected Controllers that log lubrication events and alarm histories.

-

Flow & Pressure Sensors that detect blockages or leaks in real-time, pinpointing the exact fault location.

-

Condition Monitoring Integration, where oil quality data (from moisture or particle counters) is fed into a central dashboard.

This shift from preventive (time-based) to predictive (condition-based) maintenance minimizes unplanned downtime, reduces lubricant consumption, and prevents costly machine failures.

Benefits of Effective Lubrication System Management

Investing in a proper automatic lubrication system yields a clear return on investment (ROI):

-

Extended Machine Life: Drastically reduces wear on bearings, gears, and slides.

-

Reduced Downtime: Eliminates lubrication-related failures and manual lubrication stops.

-

Lower Maintenance Costs: Saves on labor, component replacement, and lubricant waste.

-

Improved Safety: Reduces the need for personnel to access hazardous moving parts.

-

Energy Efficiency: Reduced friction directly lowers power consumption.

Read More-

https://www.zionmarketresearch.com/de/report/barrier-resin-market

https://www.zionmarketresearch.com/de/report/fiberglass-sunscreen-market

https://www.zionmarketresearch.com/de/report/lubrication-systems-market

https://www.zionmarketresearch.com/de/report/easy-open-packaging-market

https://www.zionmarketresearch.com/de/report/implantable-drug-delivery-devices-market

https://www.zionmarketresearch.com/de/report/fleet-management-systems-market

https://www.zionmarketresearch.com/de/report/automotive-glass-market

Conclusion

A lubrication system is far from an ancillary component; it is a fundamental engineering system that dictates the reliability, efficiency, and longevity of rotating and sliding machinery. From the simple grease gun to an IoT-enabled, centralized network, the evolution of these systems reflects the industry’s relentless pursuit of peak performance and operational excellence. For any operation relying on critical machinery, understanding and investing in the right lubrication system is not just maintenance—it’s a core production strategy.